Powder coating has become one of the most widely used finishing processes in industries ranging from automotive to furniture production. Known for its durability, efficiency, and environmental advantages, this technique offers manufacturers a superior alternative to traditional paint. As consumer expectations for quality and sustainability continue to rise, powder coating is playing an increasingly critical role in meeting these demands.

What is Powder Coating?

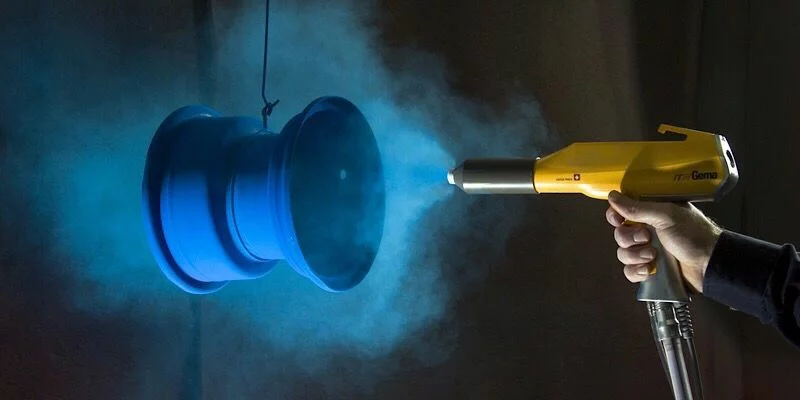

Powder coating is a dry finishing process that uses finely ground particles of resin and pigment. These particles are electrostatically charged and sprayed onto a metal surface. Once applied, the coated item is heated in an oven, causing the powder to melt and form a smooth, durable, and uniform finish.

This method has several key advantages over liquid paint. It produces a thicker, more consistent coating without running or sagging. It also minimizes waste because overspray can often be collected and reused. The result is a highly resistant finish that protects metal surfaces against corrosion, scratches, fading, and general wear.

The Advantages of Powder Coating

Durability and Longevity

One of the primary reasons industries turn to powder coating is its exceptional durability. Items treated with powder coating can withstand harsh weather, UV rays, and mechanical impact. This makes the technique especially valuable in outdoor applications such as railings, automotive parts, and heavy machinery.

Cost-Effectiveness

Although the initial setup for powder coating equipment can be costly, the long-term benefits outweigh the investment. The process reduces waste, requires fewer touch-ups, and minimizes rework. Manufacturers also save on labor, as the application process is faster and less labor-intensive compared to liquid coatings.

Eco-Friendly Benefits

Powder coating is considered one of the most environmentally friendly finishing methods available today. Unlike liquid paints, it contains no solvents, which means there are negligible amounts of volatile organic compounds (VOCs) released into the air. This helps manufacturers comply with environmental regulations while promoting greener production practices.

Applications Across Industries

Powder coating is versatile and used across a wide variety of sectors.

- Automotive Industry: Wheels, chassis, and engine components benefit from powder coating’s strength and ability to resist heat and wear.

- Appliances: Household products such as refrigerators, ovens, and washing machines often use powder-coated finishes for a sleek and long-lasting appearance.

- Furniture and Architecture: From outdoor patio sets to large-scale building facades, powder coating ensures surfaces remain attractive and weather-resistant.

- Electronics: Certain electrical components rely on powder coatings to provide insulation and protection.

The adaptability of this process makes it indispensable for manufacturers aiming to deliver high-quality, durable products.

Regional Demand and Services

In recent years, demand for specialized finishing services has grown significantly, particularly in regional hubs where manufacturing thrives. Businesses are turning to local providers who offer high-quality finishing with quick turnaround times. A great example is the availability of powder coating midlands, where manufacturers and individuals alike can access professional services tailored to their needs. Choosing a local provider allows businesses to reduce transport costs, shorten lead times, and ensure consistent quality control.

How Powder Coating Enhances Product Value

For businesses, the adoption of powder coating isn’t just about finishing a product—it’s about adding value. A high-quality coating enhances the overall appearance of items, making them more appealing to customers. Additionally, the durability of the finish reduces the risk of product returns or warranty claims, which can significantly improve a company’s bottom line.

Furthermore, powder-coated products often command a premium in the marketplace because they are perceived as higher quality. This creates opportunities for businesses to differentiate themselves in competitive markets by offering superior finishes.

The Future of Powder Coating

As technology continues to evolve, powder coating processes are becoming even more advanced. Innovations such as low-bake powders, improved color-matching capabilities, and specialized coatings for plastics and composites are expanding the possibilities of this finishing technique.

The industry is also moving toward greater sustainability. Developments in energy-efficient curing ovens and recyclable powders are reducing environmental impacts even further. With these innovations, powder coating is well-positioned to remain the preferred finishing method for manufacturers who prioritize quality and eco-friendly practices.

Conclusion

Powder coating is no longer a niche process limited to industrial applications—it is now a mainstream finishing solution valued for its durability, cost-effectiveness, and sustainability. From household items to complex automotive components, powder coating offers an unmatched combination of performance and environmental benefits. As industries continue to evolve, powder coating is likely to remain at the forefront of modern manufacturing, helping businesses create products that are both attractive and built to last.

One of the most exciting developments in the world of powder coating is its growing integration with advanced manufacturing technologies such as automation, robotics, and Industry 4.0 systems. Automated powder coating lines equipped with robotic arms ensure precise, consistent application on complex components, reducing human error and increasing production speed. When combined with real-time monitoring and data analytics, manufacturers can track coating thickness, curing times, and surface quality more accurately, leading to improved efficiency and reduced waste.

Customisation is another area where powder coating continues to expand. Modern customers demand not only durability but also unique aesthetics. As a result, manufacturers now offer a wide variety of textures, gloss levels, metallic finishes, and even functional coatings with properties such as anti-microbial resistance or thermal insulation. These advanced finishes are especially valuable in industries like healthcare, food processing, and renewable energy, where surface performance is directly linked to safety and functionality.

Sustainability goals are also reshaping the powder coating industry. Many companies are investing in closed-loop systems that capture and reuse overspray, significantly reducing material waste. New powder formulations that cure at lower temperatures are helping cut energy consumption, while research into biodegradable or recyclable powders is paving the way for a more circular production process.

Finally, the continued shift toward lightweight materials, such as aluminium and composites, is creating new opportunities and challenges for powder coating technology. Innovations in adhesion techniques and surface preparation are ensuring that powder coating remains effective on these substrates, further broadening its applications.

With its combination of versatility, performance, and environmental responsibility, powder coating is set to remain a cornerstone of modern manufacturing. As industries demand more efficient, sustainable, and high-quality solutions, this finishing technology will continue to evolve — delivering value far beyond aesthetics.