3D printers have become the breakthrough of our time. They help in various industries and even create body parts – prosthetics, which even now sounds like something incredibly fantastic and impossible. Of course, technical breakthroughs in our time are expected, and we should consider the future of such technology. So how will 3D printers affect the industry?

In the field of mass production, 3D printing can bring various changes. In general, there will be a change in the understanding and perception of mass production. There will be a shift from large batches of standard goods to small batches and individualism. The emphasis on quality may become more substantial, and products will be of higher quality and more affordable. Customized products made to order will appear. This will help improve efficiency and product quality, helping to use less natural materials. Reducing mass production will consequently reduce the amount of various biological contaminants. Also, less consumption of materials will positively impact the state of nature.

If we consider in detail the impact of 3D printing on the environment, then going deeper, we can see many positive qualities. In addition to lower consumption of materials and less pollution, the transportation of products will also decrease. In addition, the possibility of using recyclable or biologically based materials creates a strong potential for less waste.

Complex manufacturing

3D printing, or additive manufacturing, is breaking new ground in creating complex structures and shapes that are impossible or economically feasible with traditional manufacturing methods. We can now construct objects layer by layer, allowing us to design and produce one-of-a-kind, intricate structures with exquisite detail, thanks to 3D printing technology.

Using complex geometries, 3D printing enables us to produce incredibly light but durable components in the aircraft industry. This contains everything from rocket mounts to minor engine components. This strategy has the benefit of being able to decrease weight and boost efficiency, both of which are crucial for space missions.

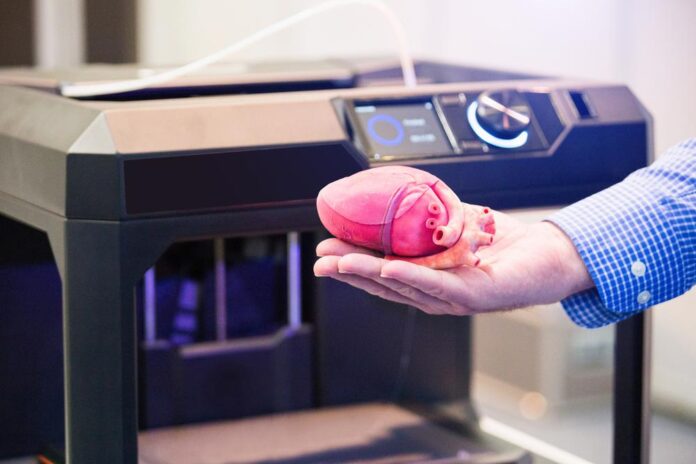

3D printing is causing big developments in the fields of medicine and biotechnology

For example, we can now print customized prostheses and implants that precisely fit the shape and size of the patient, improving comfort and functionality. Bioprinting is a newer and more promising direction that seeks to create living tissues and organs, using the patient’s cells as the “ink.”

In architecture and construction, 3D printing allows for designing and constructing complex structures that were previously unattainable. This can range from unique design elements to entire buildings being printed. Projects such as concrete house printing show the potential of this technology.

Overcoming obstacles to 3D printing

Before 3D printing can fully transform manufacturing, it must overcome several obstacles. These obstacles, including limitations in speed, material availability, quality control, and regulation, significantly impact the technology and could slow its widespread adoption.

The speed of 3D printing remains a critical issue. Currently, most 3D printers are slower than traditional manufacturing methods, especially in mass production. However, research and Innovation continue, intending to increase printing speed while maintaining high-quality products. The same waiting for the delivery of the item you need can become a lively time of production printing. In the meantime, you can take care of other things. For example, being in the company’s office while waiting for some prototype to be printed, you can schedule this time in the weekly schedule planner and spend it on other tasks.

There are also limitations in the materials available for 3D printing. A few materials still need to be printed or printed with the appropriate strength or functionality, despite the fact that the variety of materials continually expands to include plastics, metals, ceramics, and even biomaterials.

In order to maintain stability and consistency in the 3D printing process, quality control continues to be difficult. This is crucial in fields like aerospace or medical technology, where accuracy and dependability are crucial.

And last, 3D printing regulation is a complicated subject. There is still room for improvement and international harmonization in the areas of liability, intellectual property, safety standards, and laws for 3D-printed objects.

Given these difficulties, 3D printing has a lot of potential. Researchers, manufacturers, and regulators will need to work hard to get over these barriers, but we are moving closer each year to fully embracing this game-changing technology.

3D printing or additive manufacturing offers some significant advantages that can transform the production and distribution of products.

- 3D printing allows individual customization of each product without significant cost increases, a considerable advantage over traditional manufacturing methods. This means that goods can be fine-tuned to each customer’s needs, from simple items such as shoes to more complex things such as medical prosthetics.

- 3D printing can create complex structures that would be impossible or impractical for traditional manufacturing. This means you can design and manufacture products with unusual shapes, textures, or internal systems, such as lightweight but strong frameworks for aerospace applications.

- 3D printing uses additive processes that build objects layer by layer using only the necessary material. This differs from traditional manufacturing methods, which often result in significant waste.

- With 3D printing, products can be produced locally, reducing the need to transport, store, and process components made in different locations. In theory, businesses can move to digital distribution of goods, allowing customers to load and print products as needed.

- 3D printing opens up new opportunities for research and development, allowing rapid and relatively cheap prototyping and testing of new ideas. This can reduce the time and cost of Innovation, accelerating progress in many areas.