Contemporary technological advancements have bestowed us with numerous positive features, regardless of which specific industry we might shift our focus to. Still, the quality of some products and services remains unparalleled to this day, even though attempts to modify their original design and structure have been made. The outcome shows that specific standards should still not be changed, considering how effective peculiar solutions are. Thus, we would like to introduce you not only to a range of different uses of GPR grating and specific benefits it potentiates but also to numerous advantages this approach enables when compared to alternative solutions. For you to learn more about the subject, feel free to consult the lines below.

What is GRP Grating Used for?

For a layman, GRP grating’s denomination might appear as nothing special, since the abbreviation does not reveal much about its features to the uninformed. Thus, we should start with the basics, and expose any hidden details about this type of grating that might interest you.

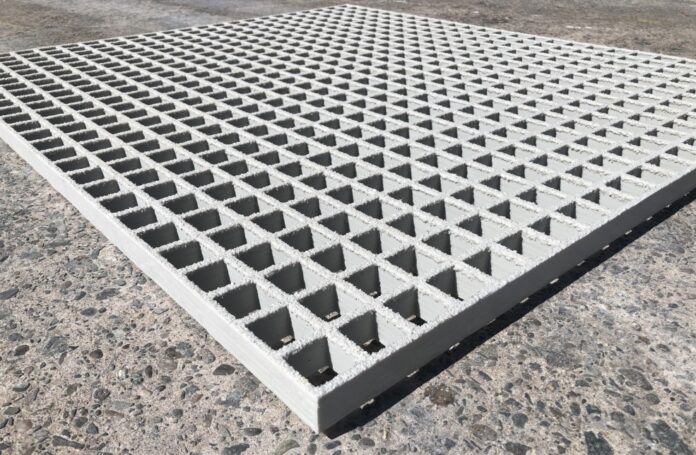

The GRP stands for “Glass Reinforced Plastic”, or fiberglass if you prefer the more recognizable denomination. Namely, it speaks about the materialization of a specific grating type and suggests potential benefits one should expect to enjoy if they decide to enhance their space with it. In a nutshell, GPR grating is used for flooring, so basically anyone who is in dire need of a floor that will outlast even the highest durability predictions and will not cost a fortune should thoroughly consider it as an option.

Anti-Slip Covering

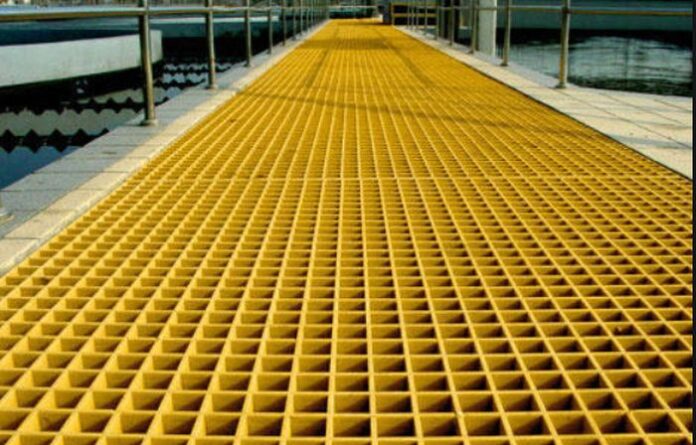

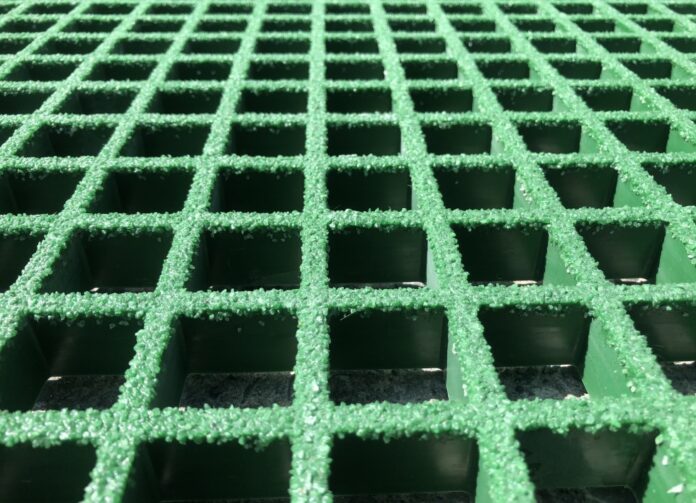

Numerous industries must secure optimal working conditions for their employees, which implies that working men should be able to perform their duties safely and as efficiently as possible. Due to its materialization, GRP grating proves to be the optimal solution in wet environments, since its structure provides both comfort and stability to the ones who use it.

Maintenance

A vast majority of construction managers seek simple but cost-effective solutions when they make plans for specific arrangements. Without question, they assess how specific materials will perform in the long run, considering various aspects that might affect the lifespan of a floor covering. That is why they often opt for GRP since the nature of the material allows it to remain uncompromised regardless of which substances it interacts with.

To make a long story short, it is astonishingly easy to clean GRP coverings, and you do not have to worry about using specific chemical cleaning agents since they should not compromise the resistant structure of GRP. When you consider how perfectly this feature matches the anti-slip characteristic of GRP, it becomes more evident why the demand for this product is high.

Increased Weight Resistance

GRP grating can stand it all, that is, if you do not try to deviate its shape by intentional force. Jokes aside, but, the level of endurance this floor covering solution provides in comparison to alternative options seems to be unreachable. Backup solutions fail to deliver the same level of immutability, which is one of the most respected features by heavy industry aficionados.

Namely, the covering should be able to handle weighty machines and resist various forms of physical stimulation and vibration from its surroundings. Fragile and inconsistent materials fail to deliver as expected, while GRP remains uncompromised regardless of which type of weight you expose it to.

Naturally, in order for the GRP grating to fit your wants and needs completely, you should learn a thing or two about what you should pay extra attention to, and https://www.grpgratingsystems.co.uk/ is where the peculiarities about it are kept.

Cost-Effectiveness

We are aware of how a limited budget might have an impact on which products one chooses to spend their hard-earned money on, but you should not worry about exceeding your earmarked funds if you opt for GRP coverings.

The production process of GRP has been perfected over the years, and which was once an expensive venture has been modified to meet both wants and needs and the pocket of a contemporary customer. The catch lies in the efficiency of the raw materials used in production, which does not cost as nearly as much as alternative solutions providing fever benefits.

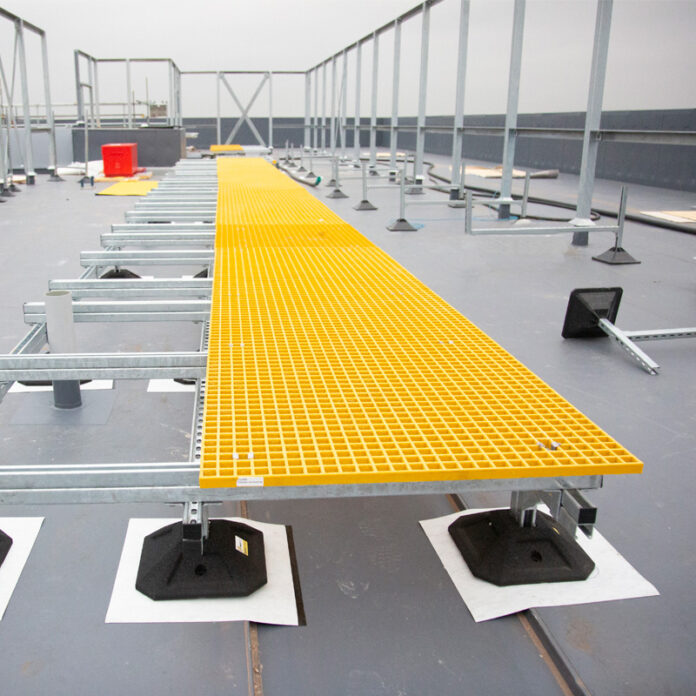

Ease of Application

Nowadays, you can find various GRP grating models on the market, so we advise you to focus on determining which one would suit you best. Selection depends on the manufacturer and the approach they potentiate. Thus, one should make their mind about whether they would make better use of square plates or they should ask for a customized solution.

Surely, customized options cost a bit more than the standard plates, but they facilitate the installment process additionally. Do not get us wrong, since the setting-up of traditional plates is not nearly as hard as placing alternative flooring options.

Anti-Corrosive

Back in the day, people used iron gratings to secure their floors, which proved to be nothing else but a temporary solution. Even though the initial setting seemed ideal, the ones using the iron grating soon noticed iron is not the ticket in the long run due to irreversible decay processes the material suffered from over a while.

Fortunately, one of the most cherished features of GRP is its constancy, since the material cannot deteriorate due to corrosion and similar chemical processes that would otherwise compromise the stability of the craft.

Heat-Resistant

GRP gratings are often installed in facilities handling high temperatures, which is why it must stay consistent regardless of how hot it might get. Otherwise, the safety of the machines and employees would be exposed to numerous risks. On the other hand, heat-resistant features are considered a must even when the temperatures hit values below zero.

Thanks to the glass fragments reinforcing the plastics, the GRP is capable of delivering regardless of the temperatures it is exposed to, thus, worry not if you intend on using GRP gratings in areas with highlighted temperature differences.

Hopefully, the aforementioned pieces of information will help you make up your mind and enhance your facility with GRP gratings. The calculus is simple, so all you should do is assess your options and find a manufacturer capable of delivering what you need.