The advancement of manufacturing technology has been pivotal in shaping the industrial landscape, and plastic extruders have been at the forefront of this revolution. This comprehensive exploration aims to unveil the mechanics behind these machines, shedding light on how they transform the plastic industry.

The Genesis of Plastic Extrusion

The concept of plastic extrusion is relatively straightforward yet ingenious. It involves melting and shaping raw plastic materials into continuous profiles. This process starts with introducing plastic pellets or granules into the extruder’s hopper, leading them through intense heat and pressure within the barrel, ultimately melting them into a malleable state.

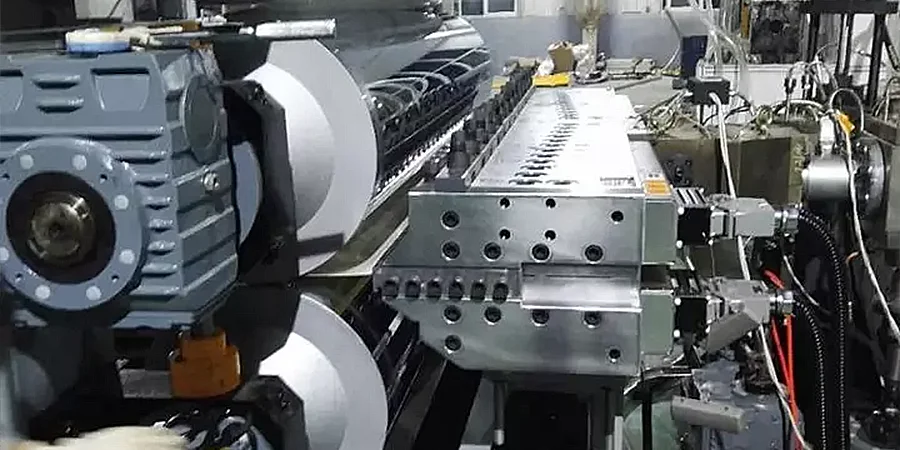

Core Components of the Extrusion Process

At the heart of this process lies the extruder, a complex machine comprising several key components: the screw, barrel, motor, and heater. The screw, in particular, plays a vital role in driving the molten plastic through the barrel, with its design significantly impacting the efficiency of the extrusion process.

Evolution in Screw Design

The evolution of screw design within the plastic extrusion industry represents a remarkable leap in technological advancement. This evolution, especially with the introduction of twin-screw extruders, has revolutionized the process, expanding its capabilities and applications beyond traditional boundaries.

The Advent of Twin-Screw Extruders

Twin-screw extruders marked a pivotal shift from the traditional single-screw systems. Unlike single-screw extruders, which rely on one screw to transport and melt the plastic, twin-screw extruders utilize two intermeshing screws. This design provides several advantages:

- Enhanced Mixing and Shearing: Twin-screw extruders offer superior mixing capabilities. The intermeshing screws create a more homogeneous blend of materials, improving the quality and consistency of the final product. This is especially beneficial when dealing with complex material compositions or incorporating additives and fillers.

- Greater Control Over Processing Conditions: The twin-screw design allows for more precise control over temperature and pressure conditions within the extruder. This level of control is critical when processing sensitive materials that require specific conditions to maintain their properties.

- Increased Flexibility and Versatility: Twin-screw extruders are highly versatile and capable of handling various materials with varying viscosities and compositions. This flexibility opens up new possibilities in product design and material innovation.

Advancements in Material Handling and Feeding Systems

The initial stage of the plastic extrusion process involves the efficient handling and feeding of raw materials into the extruder. Recent advancements in material handling and feeding systems have significantly enhanced this phase, ensuring a smoother and more consistent flow of materials. These innovations include automated feeding systems and precision weighing technologies, which meticulously measure and control the amount of raw material entering the extrusion process.

These advancements are not exclusive to extrusion but are also integral to improving the efficiency of plastic injection moulding, where precise material handling is crucial for achieving high-quality outputs. By implementing similar technologies, the injection molding process benefits from reduced material waste and enhanced production consistency, mirroring the improvements seen in extrusion.

This cross-application of technologies underscores the interconnectedness of various plastic manufacturing techniques and highlights the broader impact of these innovations.

Heating and Cooling: A Delicate Balance

The heating system in an extruder is critical for achieving a consistent melt of the plastic. The advanced heating systems ensure uniform heat distribution and reduce the risk of material degradation. Complementarily, the cooling system is integral in solidifying the extruded plastic as it exits the die, a process requiring precision to maintain the desired shape and properties.

The Die: A Mold for Innovation

The die is the final gatekeeper, shaping the molten plastic into its intended profile. The die’s design is tailored to specific product requirements, influencing the quality of the end product.

Diversity in Materials and Applications

Plastic extruders are versatile and can process various materials, including PVC, HDPE, and ABS. Each material requires specific processing conditions, a challenge met by modern machines. This versatility enables various applications spanning various sectors, such as construction, automotive, packaging, and consumer goods.

Automation and Control: Enhancing Efficiency

The integration of automation and advanced control systems has been a game-changer in enhancing the efficiency and reliability of Bausano’s plastic extruders. The sophisticated control systems allow for precise adjustments during the extrusion process, resulting in consistent product quality, reduced waste, and heightened productivity.

Environmental Sustainability: A Priority

In an era where environmental sustainability is paramount, the extruders stand out for their energy efficiency and ability to process recycled materials. This commitment to sustainability is reflected in reduced energy consumption and support for recycling initiatives, contributing to more eco-friendly manufacturing practices.

The Future of Plastic Extrusion

The potential for advancements in plastic extrusion technology is vast. Future developments are likely to see further innovations in materials, screw design, and process control. These advancements will propel the industry towards greater efficiencies and capabilities, maintaining the relevance and importance of plastic extrusion in modern manufacturing.

The Importance of Precision and Quality Control

In plastic extrusion, precision and quality control are not just beneficial but essential. The consistency of the plastic melt, the stability of the extrusion process, and the accuracy of the final product dimensions are all critical factors that determine the end product’s success. The advanced sensors and control systems ensure that every aspect of the extrusion process meets the highest standards.

Customization: Meeting Specific Industry Needs

One of the strengths of these extruders is their ability to be customized to meet specific industry requirements. Whether extruding intricate profiles for the medical industry or producing large, robust pipes for the construction sector, these machines can be tailored to deliver optimal performance for various applications.

Training and Support: Ensuring Optimal Operation

Proper training and support are crucial to maximize the potential of these sophisticated machines. Comprehensive training ensures operators have the knowledge and skills to operate the extruders effectively. Additionally, customer support and maintenance services ensure that issues are promptly addressed, minimizing downtime and maintaining productivity.

The Impact of Material Innovations

The plastic extrusion industry is also greatly influenced by innovations in material science. Developing new plastic formulations with enhanced properties – such as increased strength, flexibility, or heat resistance – opens up new possibilities for product design and application. The extruders can adapt to these new materials, extending their applicability and usefulness in various industries.

Global Reach and Industry Influence

The impact is not limited to a single region but is felt globally. Plastic extruders are used by companies worldwide, contributing to the development of products we encounter in our daily lives. From household items to critical components in various sectors, the influence of this technology is widespread and significant.

Embracing Industry 4.0

Industry 4.0 has brought about a new era in manufacturing, and plastic extrusion is no exception. Integrating IoT (Internet of Things) capabilities and advanced analytics into the extruders enables predictive maintenance, real-time monitoring, and optimization of the extrusion process, leading to smarter, more efficient manufacturing.

Conclusion

The world of plastic extruders is complex and fascinating, blending engineering, material science, and technology into a process that shapes countless aspects of our modern world. With their advanced technology, precision engineering, and commitment to sustainability, these machines stand as a beacon of innovation in this field. As we continue to witness advancements in plastic extrusion, these machines’ significance in shaping our everyday items and our future cannot be overstated.